Seamark stacking battery X-ray inspection machines are suitable for the inspection of stacking (blade) process-type cells in the lithium battery industry and can adopt TDI line scanning technology and expandable inspection functions such as plate fold and tab fold. Seamark has 2 kinds of stacking battery X-ray inspection machines, inline and offline. Customers can choose the suitable product according to different requirements.

Various stacking process types of batteries can be inspected by using the Seamark offline stacking battery X-ray inspection machines. Random inspections are frequently conducted using offline inspection equipment. It uses an advanced FPD and professional Hamamatsu X-ray tube, which may assist the operator in acquiring a clear image of the samples and making the right decisions. In some labs and small battery manufacturing businesses, it is commonly used.

Seamark's XB7200 inline stacking battery X-ray inspection machines offer automatic inspection for multi-layer stacking power batteries. Using advanced imaging technologies, it assesses aspects like weighing, folds, and creases, ensuring high-quality stacking batteries vital for the new energy car industry's reliable performance.

Seamark values the collaboration and R&D with the world's leading manufacturer of X-ray tubes. It adopts the Hamamatsu X-ray tube, which is one of the best industrial X-ray tube manufacturers around the world.

High dynamic: Breaking through the limitations of X-ray tubes.

Fit: The model is more stable.

Multi-fusion: multi-operator fusion.

Clarity: Large image quality.

Professional R&D department and after-sales service engineers group provide you with patient and professional technology support to make sure customers use equipment efficiently and easily.

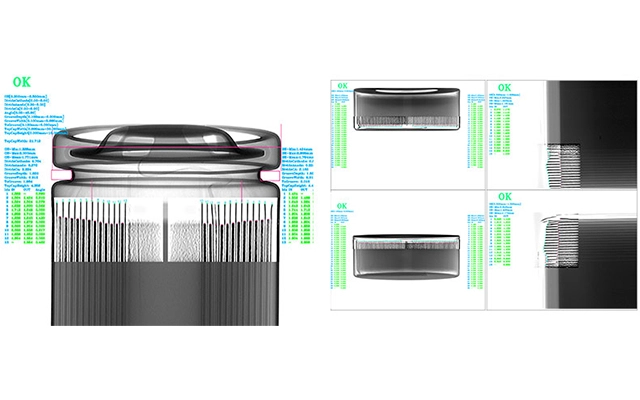

The stacking battery X-ray inspection machine is specialized equipment designed to assess the internal structure of stacking batteries. It plays a crucial role in inspecting various parameters like overhang, plate fold, tab fold, and large area fold, all of which are essential indicators of battery quality. Utilizing advanced technology, this machine incorporates an X-ray tube and an FPD/TDI camera, enabling it to generate clear and detailed images. These images are instrumental in revealing the intricate internal structure of different battery samples. By providing precise insights into the quality of batteries, this inspection machine ensures the production of reliable and high-performance stacking batteries for various applications.

This kind of equipment is typically used for sporadic checks and is appropriate for laboratories or batteries without stringent production standards. It can assist the battery manufacturer in making an informed decision and save time.

In the fully automatic battery production line, this kind of equipment is often used for a thorough inspection, making it perfect for manufacturers who are demanding quality control. It ensures that all products meet standards.