The stacking battery adopts multi-tap parallel welding, which has less internal resistance, lower volume energy density, and uniform internal temperature distribution. At the same time, the force area between the electrode plates is the same, with no obvious stress concentration point, making the internal structure more stable. However, it should be noted that the manufacturing process of stacking batteries is relatively complex, requiring multiple layers of positive or negative electrode tabs to be welded together. This can easily lead to faulty soldering during the manufacturing process, making the operation more difficult.

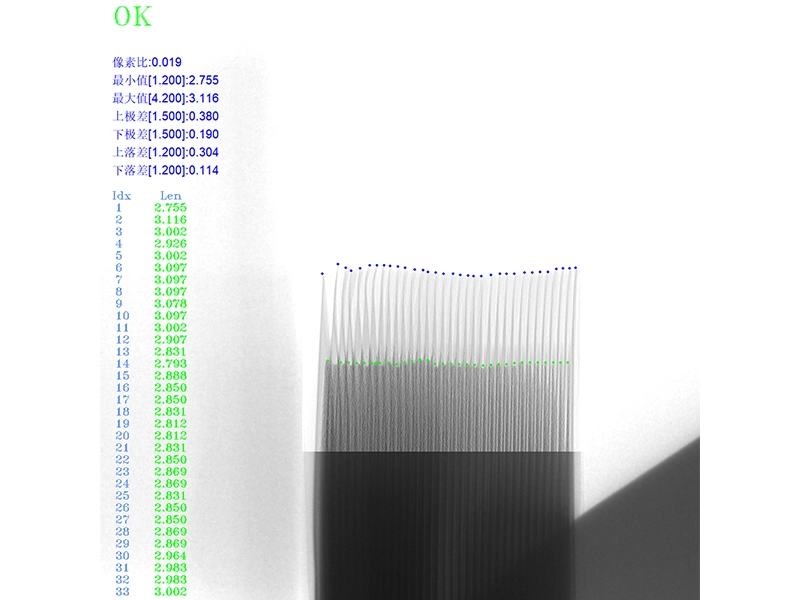

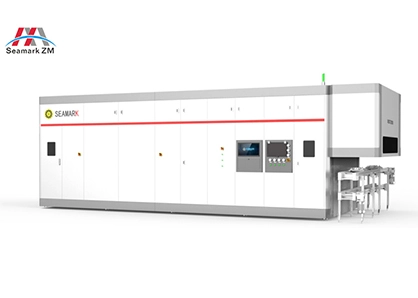

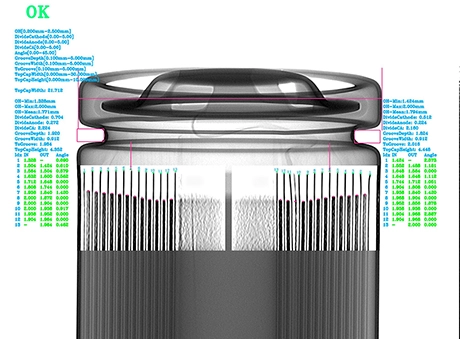

Seamark's stacking battery x-ray inspection machine can accurately measure overhang, identify wrinkles in plate folds, tab folds, and shapes, and determine the yield rate in the production process. We call the x-ray technology used in the stacking battery industry stacking battery x-ray inspection.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe čeština

čeština Polska

Polska Malay

Malay हिंदी

हिंदी magyar

magyar Indonesia

Indonesia اردو

اردو