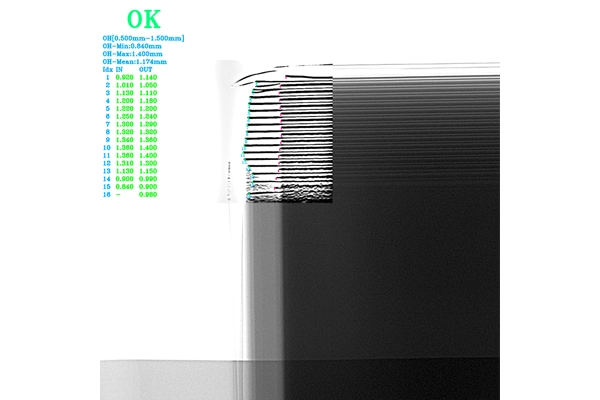

Seamark has three models of inline-winding battery x-ray inspection machines: the XB7100, XB7300, and XB8100. Inline automated X-ray inspection machines are popularly used for different kinds of winding batteries. For example, XB7100 achieves fully automatic inline inspection of multi-layer winding power batteries, inspecting the alignment of positive and negative electrode plates, large surface folds, tab pulling pins, etc. of winding power and energy storage batteries. XB8100 is compatible with φ14-φ46mm cylindrical batteries. In order to meet the inspection requirements of multi-layer high efficiency under different diameters, area array sampling technology or TDI line scanning sampling technology is selected. The inspection contents include angle overhang, resistance value, conductivity, etc.

Winding Inline Inspection Machine

Winding inline automated X-ray inspection plays a pivotal role in modern manufacturing processes, ensuring the production of high-quality goods while optimizing efficiency and reducing costs. By inspecting each product in real-time as it moves down the production line, manufacturers can guarantee the accuracy and quality of their products. This real-time monitoring not only prevents defective items from reaching the market but also provides valuable data for process optimization. By analyzing the rate of qualified products, manufacturers can identify patterns in defects and make necessary adjustments to their production methods, machinery, or materials. This data-driven approach not only enhances product quality but also significantly cuts down on manufacturing expenses in the long term.

Different automated X-ray inspection machine models have different parameters. For the accuent PPM, please contact with the service or the salesman directly.

The machine can be customized for different requirements. You only need to tell us your requirements, and our R&D team will provide the solution for you.